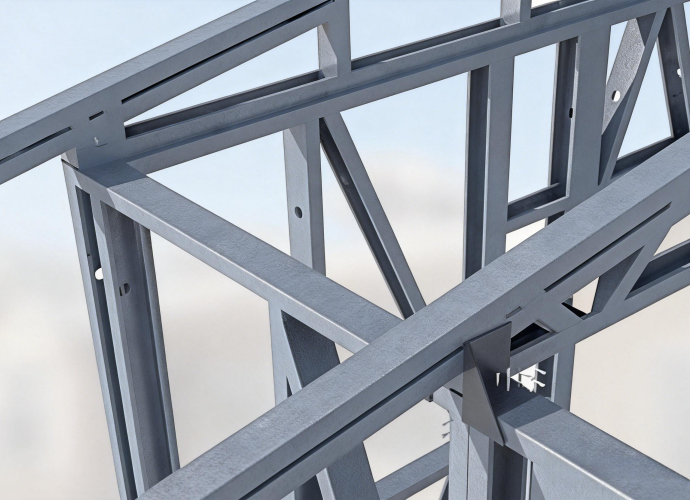

Light guage steel villas, also known as light steel frame houses, primarily utilize light steel studs made from hot-dip galvanized steel strips through cold-rolling technology. Through precise calculations and supported by auxiliary components, they achieve optimal load-bearing capacity, serving as a replacement for traditional housing structures. Mainly used for houses, home, resort, holiday, hotel, hospital and other long life span residential buildings.

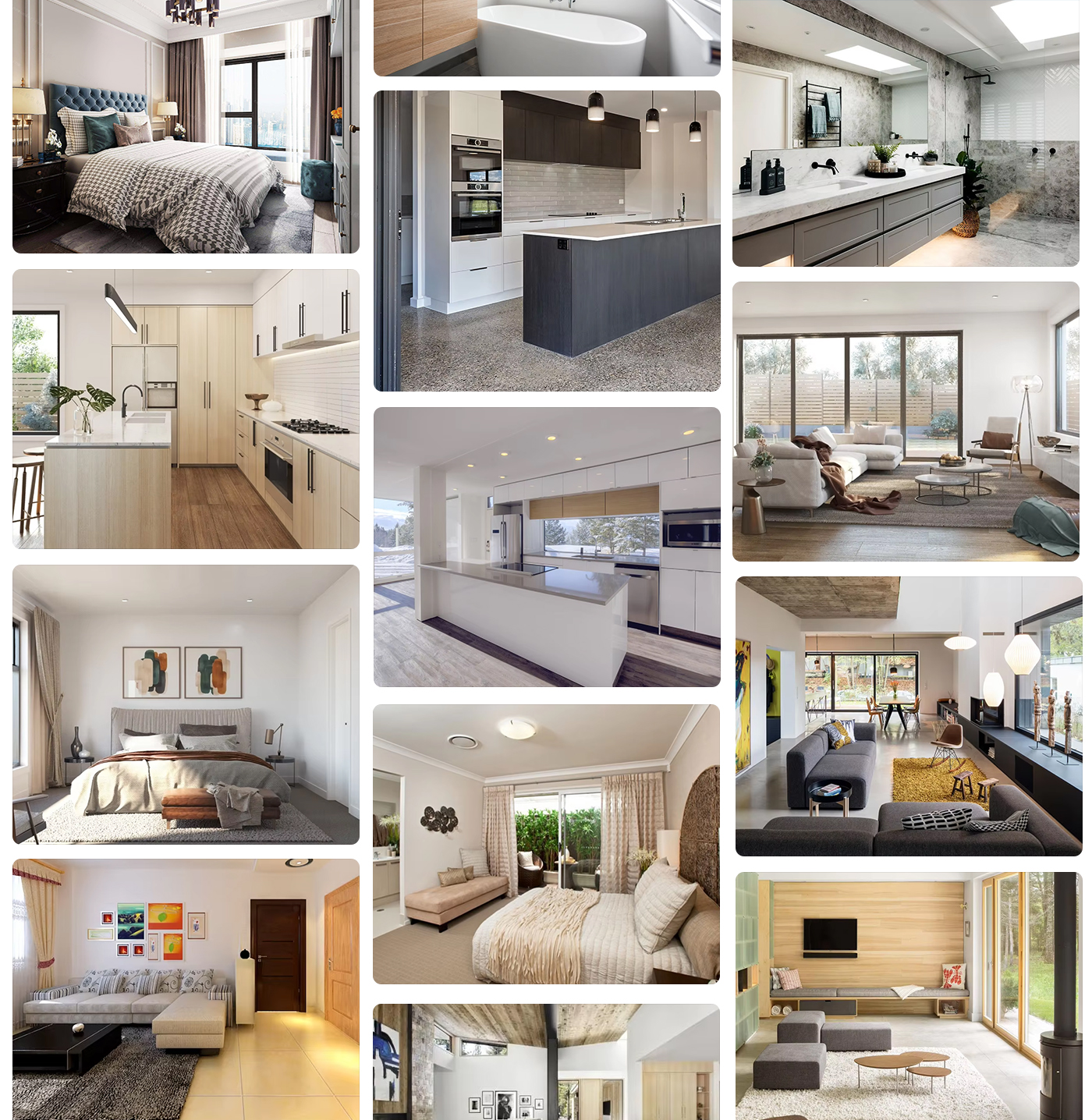

With luxury decoration and various types, it’s been more and more popular of middle & high standard market. It’ s a new type of building structure system, which is formed by the main steel framework linking up H-section, Z-section, and U-section steel components, other components such as windows and doors, can be chosen by the customers.

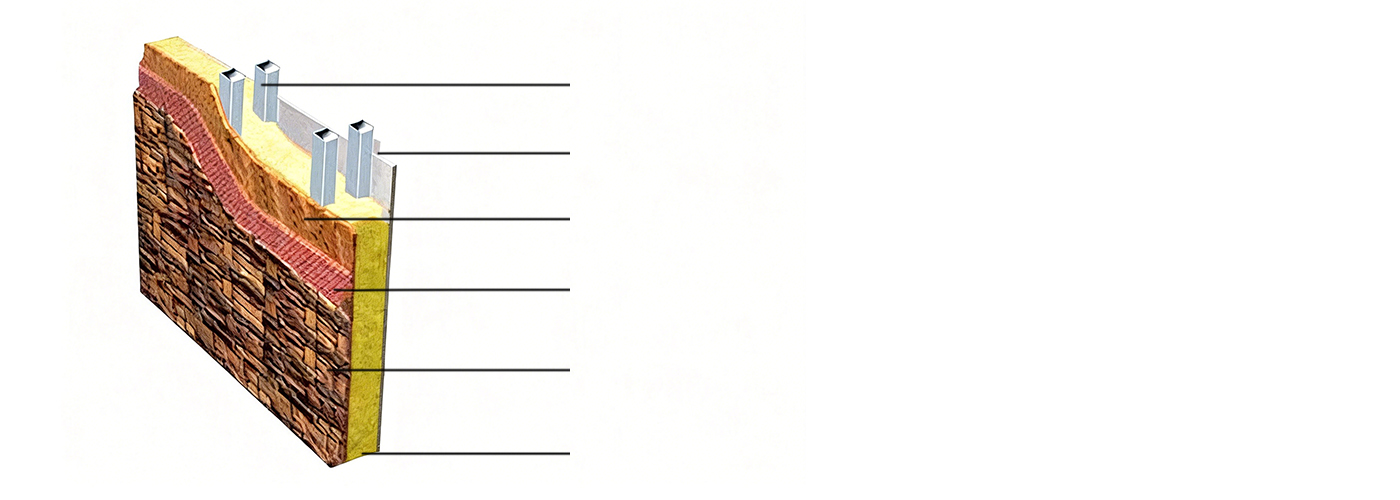

| Steel Structure | Light Guage Steel villa is more stable than the one that made of welding frame steel. Besides, it is cheaper, more economic. with long lifespan, which can last almost 70years,all the materials of light guage steel villa is Q550. It is locked with bolts, which can be used repeatedly with out any maintenance. |

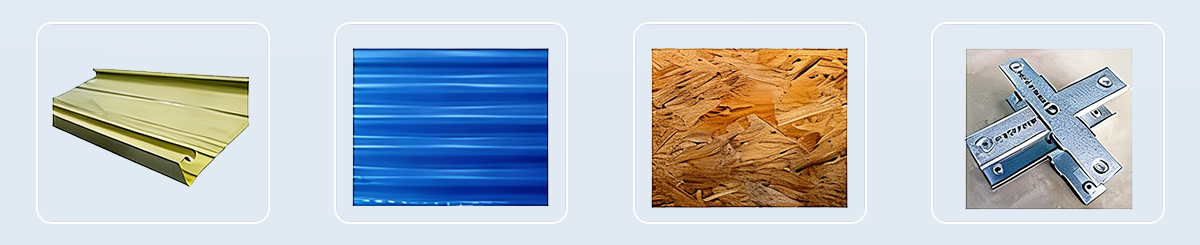

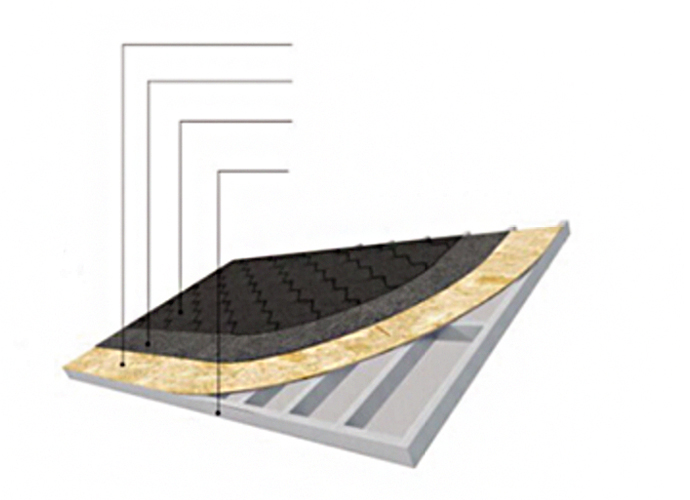

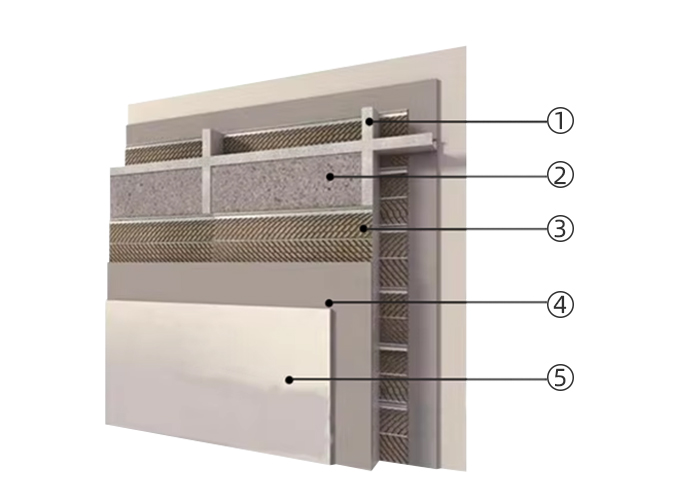

| Flooring | Decoration: PVC flooring, carpet, laminated flooring, solid wood flooring Floor: Plywood, galvanized deck+concrete, calcium silicate board lnsulation layer: Glass wool Floor beam: Rectangular tube, pipe truss, truss angles, hot-rolled steel Floor purlins: Rectangular pipes and C-shaped steel Ceiling: calcium silicate ceiling |

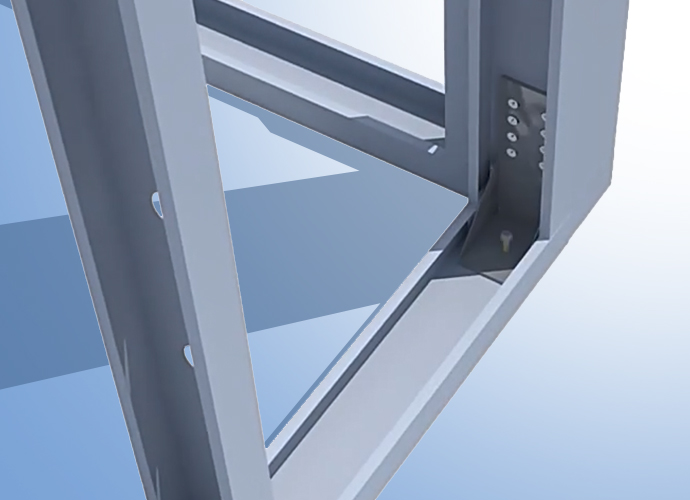

| Windows and Doors | Windows: Double glazing plastic-steel or aluminum alloy thermal-insulating frames Doors: steel security gate doors; wood or molded doors |

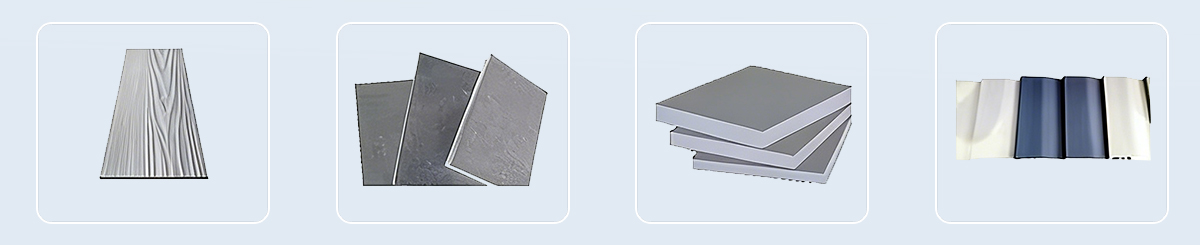

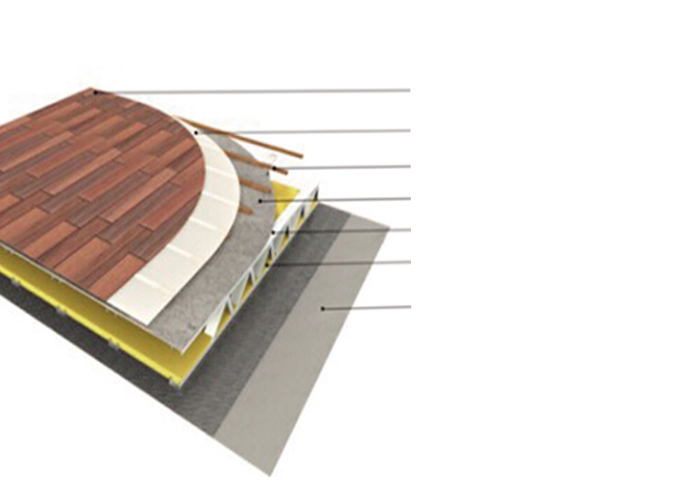

| Composite Wall System (thickness:150-250mm) | Decorative layer: PVC cladding, PU metal cladding, single metal cladding, calcium silicate board lnsulation: EPS sandwich panel, PU sandwich panel, glass wool sandwich panel Ring beam: Cold rectangular tube, pipe truss. Steel column: Cold rectangular pipe, hot rolled steel H |

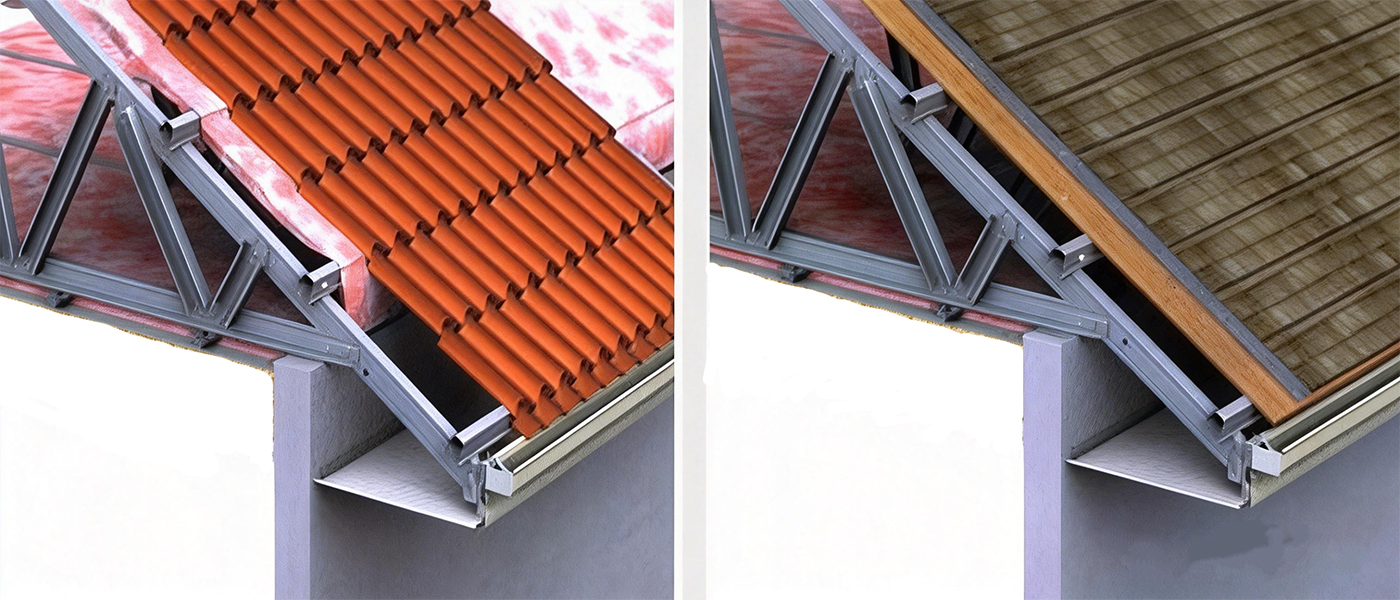

| Roofing System | Asphalt tile Cement tile Clay tile Color steel tile Glass fiber tile |

| Please contact us for your specific requirements. | |

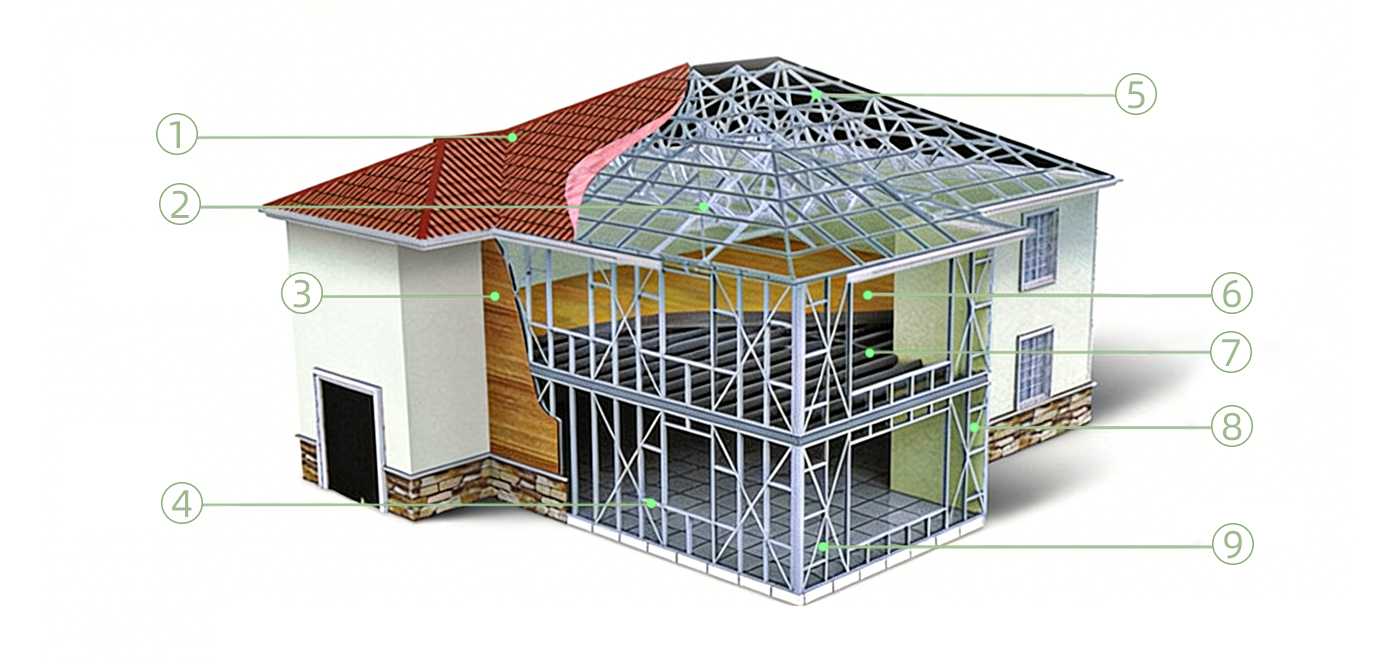

| 1 | Metal Roof Tile | 4 | Rigid Bracing | 7 | Floor Joist |

| 2 | Roof Batten | 5 | Roof Truss | 8 | Cross Bracing |

| 3 | Structural Wall Sheathing | 6 | Floor Structure | 9 | Wall Assembly |

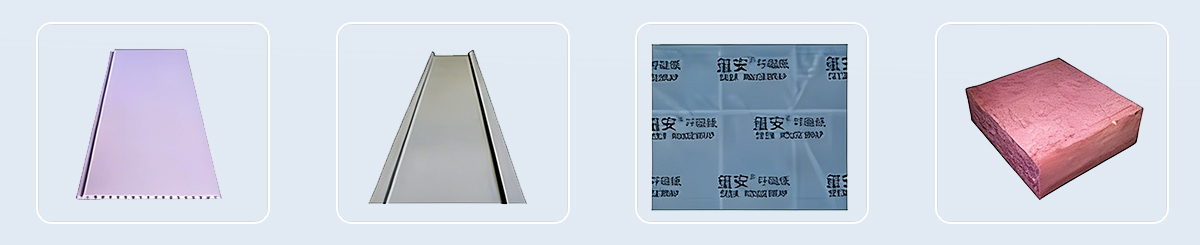

Roof system

Floor system

Wall system

Grouting

Light gauge steel villas adopt prefabricated construction methods, enabling fast on-site assembly with minimal noise and dust. This significantly reduces disruption to surrounding environments and supports civilized construction practices. The steel structure is recyclable, making it an environmentally friendly and sustainable building solution.

Earthquakes generate both lateral and vertical forces. Light gauge steel structures are connected with high-strength screws to form an integrated load-bearing system, creating a stable structural “box.” This effectively prevents wall collapse or floor failure during seismic events, ensuring occupant safety.

The main structure is constructed from cold-rolled, hot-dip galvanized light gauge steel, offering excellent corrosion resistance. Key structural connections are assembled using stainless steel rivets and high-strength screws. Under normal operating conditions, the structure is designed for a service life of up to 70 years.

Under the same seismic performance standards, the overall construction cost of light gauge steel villas is typically 20%-30% lower than that of traditional brick-concrete buildings. In addition, the construction period can be reduced by 40%-60%, significantly improving overall project efficiency.

Supported by an in-house architectural design team, we provide complimentary customized design services based on your site conditions, floor area, and functional requirements—creating a home that is truly tailored to your needs.

PU metal carved sandwich panel

PU metal carved sandwich panel